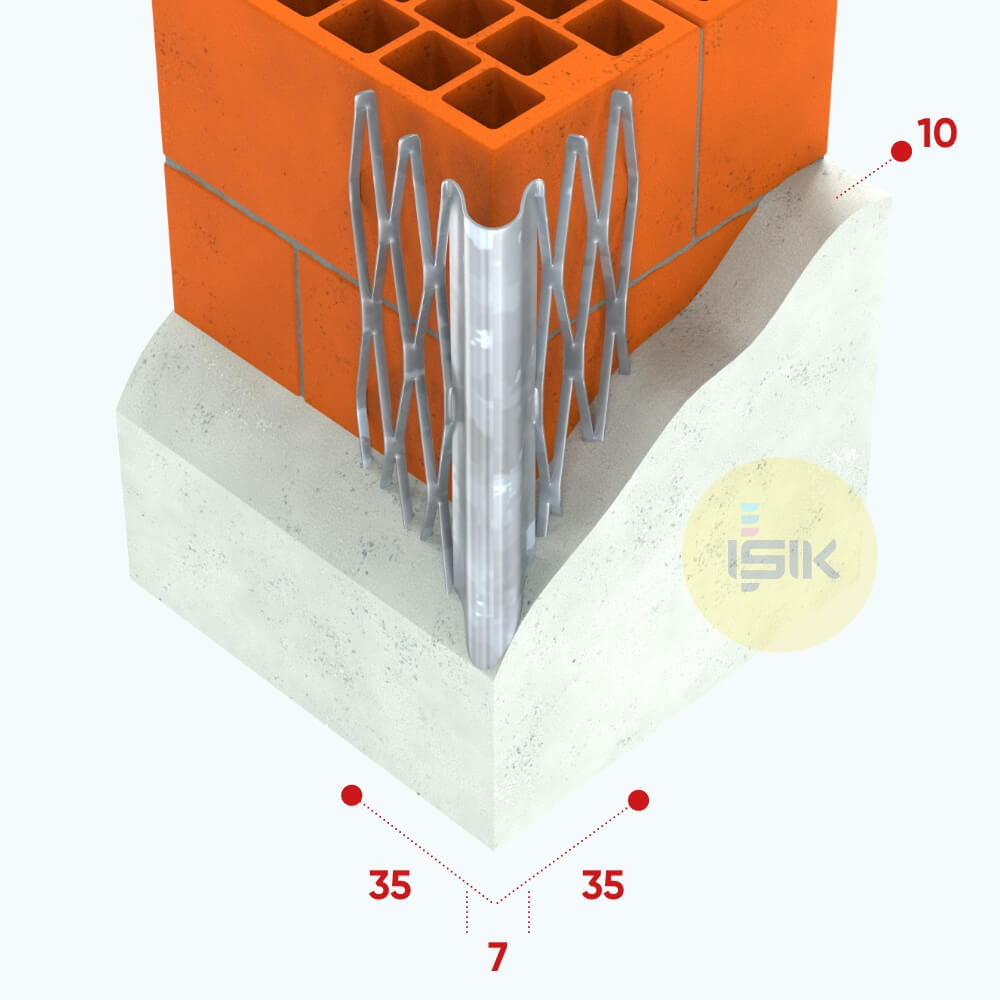

Model Number

G1000

Application Area

Interior plaster

Plaster Depth

10 mm

Profile Wings

35x35 mm

Surface Treatment

5-mesh

| Article number | Material Thickness | Standards | Lengths | Pack Qty. | Pallet Qty. | |

|---|---|---|---|---|---|---|

| add to List | G10005500 | 0.50 mm Z275 | EN 13658-1 | 150, 160, 180, 200, 220, 225, 240, 250, 260, 270, 275, 280, 300 cm | Bundle: 25 pcs | 100 bun. |

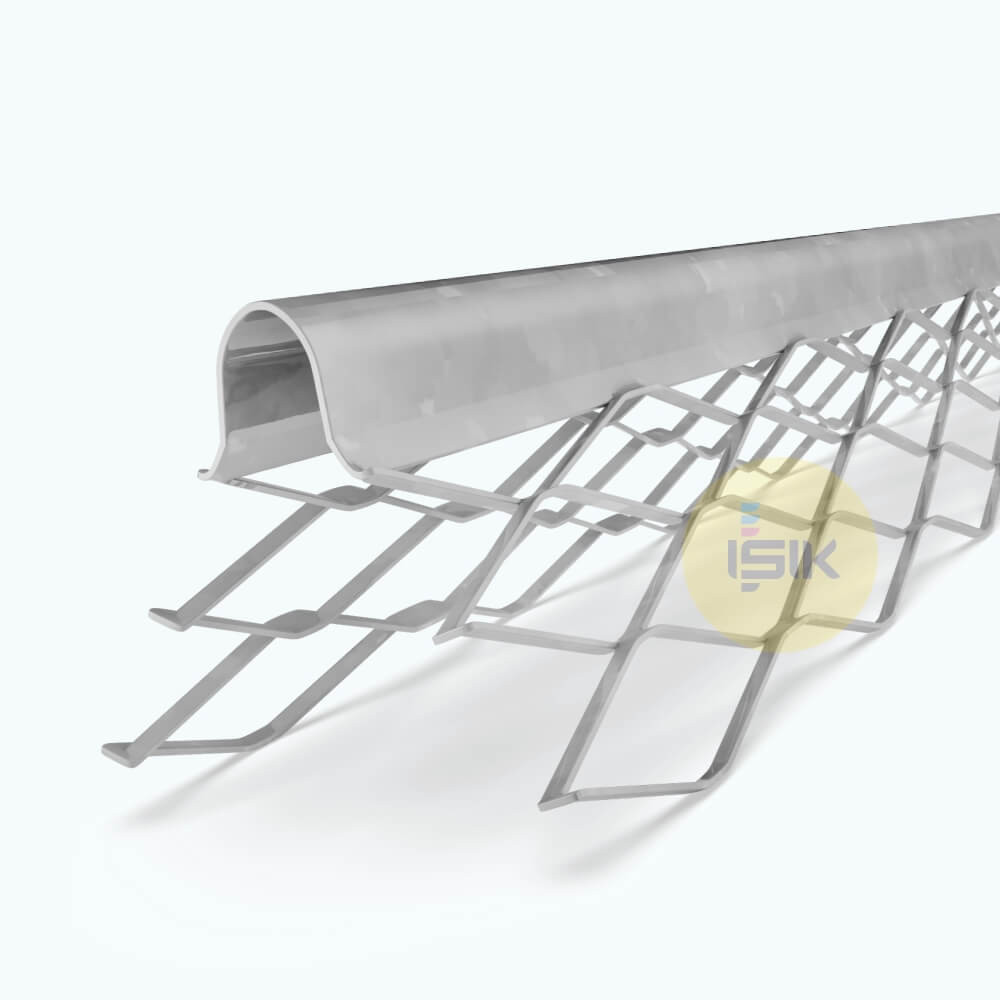

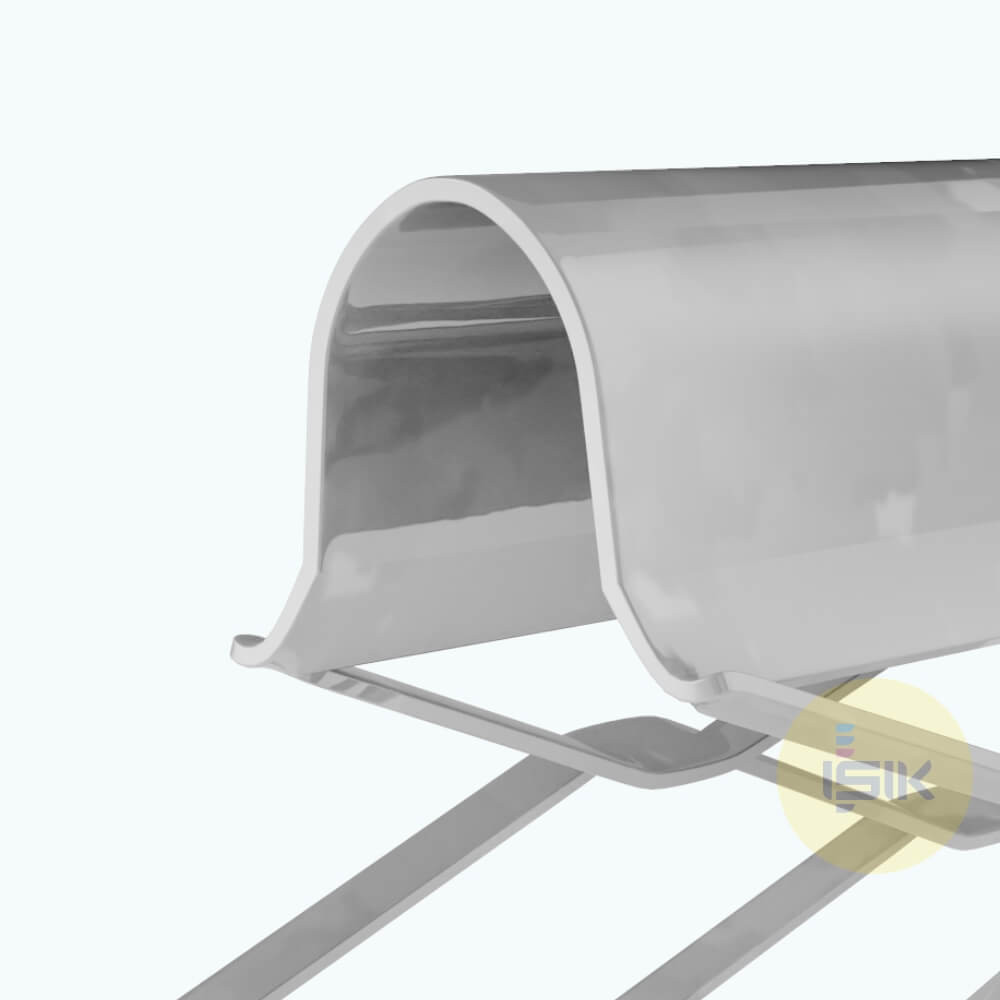

Description

G1000 provides true and straight arris. Prevents chipping and cracking to vulnerable corners. The expanded metal meshes ensure that the bead is firmly embedded in the plaster. Flanges can be easily flexed over irregular, uneven surfaces with a significant cost advantage.

Applications

- Suitable for interior applications.

- Not suitable for external applications unless secondary protection against corrosion is provided.

- Not permitted for areas exposed to high moisture and dampness after application. (houses in wooded areas, wet rooms, swimming pools, and domestic bathrooms, etc.)

Compatibility

- Suitable for lime, cement, lime-cement, or gypsum-based plaster applications.

Materials

- Manufactured with DX51D+Z galvanised steel strips with zinc coating in accordance to EN 10346.

- Z275 Zinc coating of 275 g/m 2 on both sides. Meets EN 13658 parts 1&2 and EN 14353 applications.

- Z100 Zinc coating of 100 g/m 2 on both sides Meets EN 14353 applications.

- Z60 Zinc coating of 60 g/m 2 on both sides. Meets no standard.

Installation

- Should be fixed with plaster or render dabs. Adhesive mortars with set accelerators containing chlorides are not suitable for fixing galvanised profiles.

- Not resistant to corrosion when using topcoats of less than 3mm depth in exterior areas.

- Should not come into contact with aluminium or stainless steel profiles.

- Cut with hand plate shears across the wings and a fine-toothed saw across bead noses.

- Should be fixed in accordance with embedding the bead’s wings into the plaster.

Notice !

Make sure that you choose the most suitable profile material and plaster mortar according to the application area to avoid excessive risks, claims, and consequential damage. To prevent bimetallic corrosion, ensure that all metal components used in a given installation are of the same material type. Please ensure sufficient aeration to prevent corrosion and accelerate the drying time. Avoid damage to beads when trowelling plaster or render. Care should also be taken to prevent mechanical damage to the galvanised coating. The substrate must be dry, clean, dust-free, absorbent, and load-bearing in accordance with the requirements of the plaster coats to be applied. The wall surface must not contain salts or foreign substances and efflorescence must be removed. In general, metal beads should be kept dry and stored flat.

Downloads

Description

G1000 provides true and straight arris. Prevents chipping and cracking to vulnerable corners. The expanded metal meshes ensure that the bead is firmly embedded in the plaster. Flanges can be easily flexed over irregular, uneven surfaces with a significant cost advantage.

Applications

- Suitable for interior applications.

- Not suitable for external applications unless secondary protection against corrosion is provided.

- Not permitted for areas exposed to high moisture and dampness after application. (houses in wooded areas, wet rooms, swimming pools, and domestic bathrooms, etc.)

Compatibility

- Suitable for lime, cement, lime-cement, or gypsum-based plaster applications.

Materials

- Manufactured with DX51D+Z galvanised steel strips with zinc coating in accordance to EN 10346.

- Z275 Zinc coating of 275 g/m 2 on both sides. Meets EN 13658 parts 1&2 and EN 14353 applications.

- Z100 Zinc coating of 100 g/m 2 on both sides Meets EN 14353 applications.

- Z60 Zinc coating of 60 g/m 2 on both sides. Meets no standard.

Installation

- Should be fixed with plaster or render dabs. Adhesive mortars with set accelerators containing chlorides are not suitable for fixing galvanised profiles.

- Not resistant to corrosion when using topcoats of less than 3mm depth in exterior areas.

- Should not come into contact with aluminium or stainless steel profiles.

- Cut with hand plate shears across the wings and a fine-toothed saw across bead noses.

- Should be fixed in accordance with embedding the bead’s wings into the plaster.

Notice !

Make sure that you choose the most suitable profile material and plaster mortar according to the application area to avoid excessive risks, claims, and consequential damage. To prevent bimetallic corrosion, ensure that all metal components used in a given installation are of the same material type. Please ensure sufficient aeration to prevent corrosion and accelerate the drying time. Avoid damage to beads when trowelling plaster or render. Care should also be taken to prevent mechanical damage to the galvanised coating. The substrate must be dry, clean, dust-free, absorbent, and load-bearing in accordance with the requirements of the plaster coats to be applied. The wall surface must not contain salts or foreign substances and efflorescence must be removed. In general, metal beads should be kept dry and stored flat.

Downloads

item successfully added to your list.

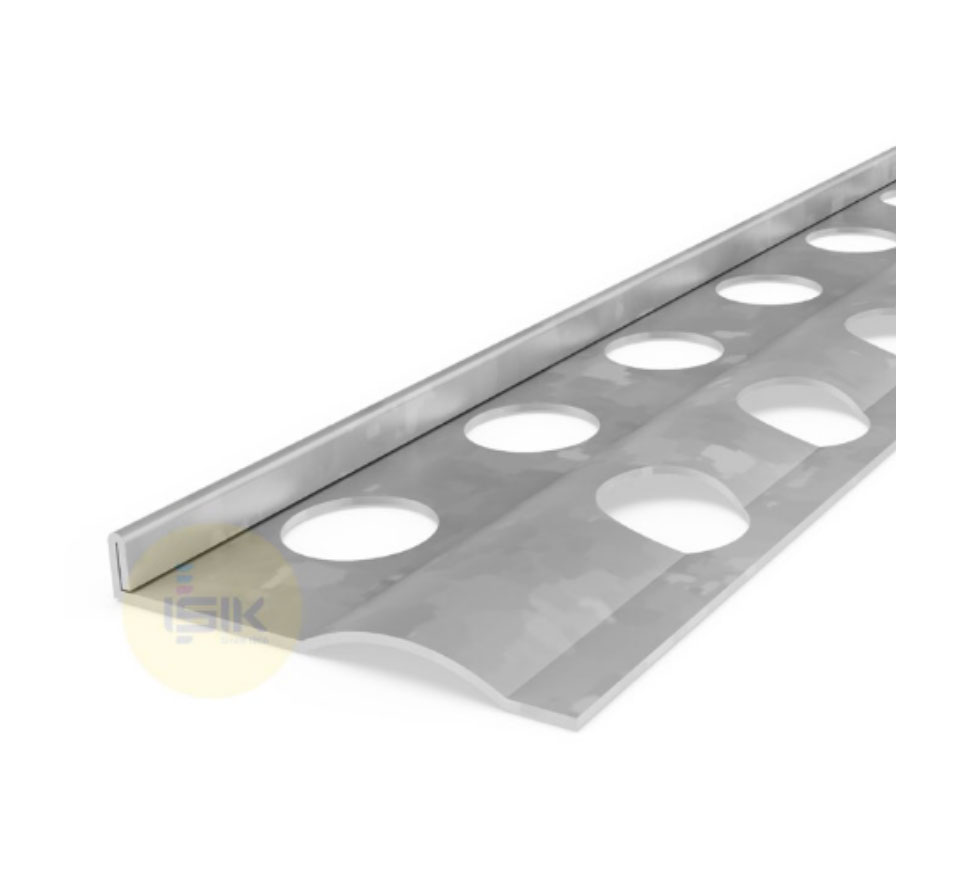

G10105500

Galvanised Steel Corner Bead with PVC nose

0.50 mm | Z275 | Bundle | 2500 pcs